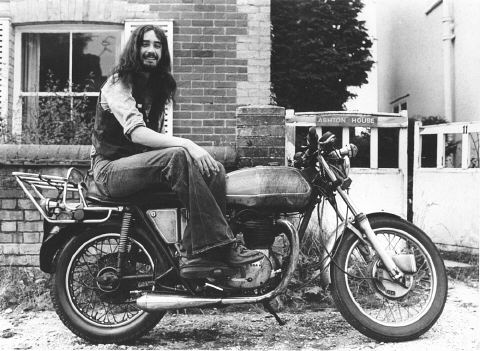

1973

BSA A65 Lightning

Bought in 1976 for £550, my first 'proper' bike. A 650cc parallel twin, she was one of the last A65s registered, in 1973, and had the nicest lines of all the BSA unit 650s I thought, despite the rather challenging green and white paint job the previous owner had given her (when I took her to college she was nicknamed 'The Bathroom Suite' by the other Brit bike owners - be grateful only one colour picture survives - er... thank you Pete Isted!).

Oil in a frame that didn't carry enough, she served me well for about 6 months until I blew her up the first time. In traffic on the way into work I trickled to the front of the queue at the lights where three lanes were about to reduce to two. A truck and a bus on my left, a car to the right, I sit there in first with the clutch in, the lights change, I drop the clutch… and the engine bogs as the bike staggers forward, bugger that must have been second. Slip clutch and give her more revs, engine howls, bike reluctantly moves forwards some more, car and bus now converging on me so I pull in the clutch, stamp right foot down to engage first, drop clutch, bike jumps forward like a goosed kangaroo and I lose my grip on the left hand bar. Make no mistake, for a 650 the A65 had a surprising turn of speed - a year or so later I gave a friend on a then new Kawasaki Z900 a standing start drag (Double Overhead Camshaft it said - dead impressive), and up to 65 the BSA was the quicker. Today, though, I really wanted her to slow down but unfortunately I couldn't release the throttle until I got a grip with my other hand. This I did in probably less than a second, all the time watching the tacho go through 6, 7, 8 thousand rpm (power started to drop off here), to just before 9,000 when a loud and expensive sounding bang coincided with the power virtually vanishing and my regaining control of both bars. By now I was 200 yards clear of the other traffic, which promptly came past me. But she was still running, albeit trailing a long plume of smoke, so I limped the ten miles or so into work, bike sounding like the original bag of nails, where, in the car park, she stopped dead - seized as solid as a Leyland walkout.

Next summer I got her home and treated her to a bit of love and affection, ahem. Siamese pipes, reverse cone megaphone and new second hand gearbox. All quick and easy to fit, pipe reduced weight and, most importantly, all cheap. Also fitted a smaller gearbox sprocket for more acceleration (stupidly big job this as you've got to go through the gearbox or split the crankcases to get at it). There was a tad of a misfire, too, at high revs, so I fitted new condensors. I also fitted a new Zenor diode, stopping the battery boiling, and a new throttle cable. The original one of the one into two broke so to get home I tied the inner to my belt and tried to control revs with my body position. This didn't work too well at first as it was hard to stop accelerating; judicious use of the kill switch got that problem under some sort of control and I got home in one piece but put a new cable at the top of my parts to get list.

All sorted I rode her back up to Wales in September. And as I got on the M4 I realised she wasn't all sorted at all - that misfire was still there and getting worse. By the time I reached Swindon it was getting bad at 3500 rpm, so the rest of the journey was spent at as close to 3500 as I could manage. It took a long time. Back at the digs I replaced the condensors - still no luck. Carbs seemed fine so reluctantly decided to whip the head off, once again in the open air. All seemed fine as I examined the head, and then had a peak at the piston crowns. Each inlet valve cut away had a neat half moon apparently cast into it… oh dear. Yup, the springs had given up the unequal struggle against constant over-revving, and in retrospect I think I was pretty lucky not to drop a valve. Both were noticeably bent, both were replaced, new pistons were sourced and the misfire finally vanished for good.

So, what was she like to ride? Surprisingly good, actually. About as fast as a 750 Bonneville and handled as well (which meant a lot better than the contemporary Japanese bikes - Honda CX500s, Suzuki Hustlers, CB200s etc). I remember one bike club run where we took about half a dozen bikes (mine the only Brit) to the top of the Llanberis pass, stopped for a cup of tea, then came down the south side. Lovely twisty road, lots of open corners and reasonably steep. So I set off last, kicked the BSA into neutral and switched her off, and coasted down the mountain hands off, steering with body weight slowing with rear brake and passing all the other Jap bikes on my way. Most enjoyable, though it didn't really make up for the overall lack of reliable power - strictly speaking she was no faster than a typical Japanese 250, and you could guarantee that if you tried to keep up with one for more than about 10 miles something on the BSA would break or drop off: vibration over 4000 rpm was fearsome.

One benefit, though, of an overall lack of reliable power, was that the brakes were never over-exercised. This was good as they were bad. The rear was actually more powerful than the front and it took me years on other bikes to get out of the habit of relying on the rear and the gearbox to slow down. My A65 had the conical (aka comical) hub twin leading shoe on the front, which on the face of it should have been pretty powerful. But rather than a rod activating the second shoe, a design that had worked perfectly well on a previous generation of BSAs, Nortons and Triumphs, BSA elected to cost cut by having the brake cable outer activate it by pushing against the cam as the inner pulled the other cam. Cable outers can compress, of course, and when you applied the brake that's exactly what happened. Retardation was minimal, despite putting a fair bit of time and effort into mounting and adjusting both sets of shoes to bite the drum simultaneously. And as if this lack of power wasn't enough, it got very hot as well, despite an air-scoop on the front big enough to swallow sparrows. I remember testing the front brake after meticulously setting it all up: nice straight road somewhere on Anglesey, up to 95mph, apply front brake. Slowly down to 75mph, then it seemed to bite better and speed rapidly came down to about 50mph (though not rapidly enough to provoke any howls from the front tyre). And then it just faded away - lever came back to the handlebars, bike actually felt like she was speeding up and again I had to resort to the back brake to come to a halt.

Very solidly built though. I'd returned to college minus MOT one September (I'd phoned from Hampshire to book the MOT in Wales), and coming into Beaumaris the next day with a Welsh chum on the back a car turned right as I was overtaking it. I swung right but couldn't avoid it and bounced off the wing, up the pavement, off a wall all the time trying to regain control as pedestrians dived for cover and Roland, my pillion, clung on for dear life. And succeeded, parked up, inspected the damage (bent left foot peg, scratched clutch and brake levers, sore knee), and limped back to the offending car. Which was a mess. The foot peg had punctured the front offside tyre, my knee had lightly creased the middle of the wing, and the left handlebar and clutch lever had gouged the top of the wing, popping out the headlamp which lay smashed on the floor. The driver was a tourist, from Liverpool I think, and while none too happy agreed fairly quickly that we'd come out even and to leave it at that; I was lucky that my pillion spoke fluent Welsh (and very volubly once the shock wore off) so all the witnesses were on my side. Just as well, because I suspected that had the law got involved they'd've taken a dim view of my lack of MOT (the appointment had been for the previous day and I'd not bothered to reschedule it, tut tut).

Electrics weren't bad either, 12 volts, car type sealed beam front (with no parking light), indicators that worked and Lucas 'butterfly' switchgear, unlabelled which the press at the time disliked but I had no problems with. Dip and full beam on the left, indicators on the right and two push buttons on either side, for kill switch (this was before the days of positive kill switches), headlamp flash and horn, plus one spare. Funny thing with the headlamp flash was that towards the end of my ownership the bike definitely went faster with the flash on - I could feel a power increase as I pressed it. Presumably something to do with alternator coils being pulled into service, but I never got to the bottom of the problem as the bike was stolen shortly after I moved back to England. Never seen again, a real shame - but if anyone out there knows the whereabouts of SWL 877M, engine/frame number A65L NG2255 (I'm pretty sure of that number), give me call. I'd love to see her again and make up for my earlier treatment by lavishing some proper care and attention on her!

Then, of course, her troubles really started. As my sole means of transport for the next three years I drove her just about every day. Student grants weren't too generous then and offers of cheap beer were, so maintenance as far as the BSA was concerned was limited to buying petrol and bolting back on the bits I noticed coming loose - carbs, for example, and foot pegs and indicators. And rear brake levers. And tacho drives. And pannier mounts. And handlebars… actually, in retrospect, it would have been cheaper overall if I'd spent a little time with spanners tightening some of the bits I'd not notice falling off. Like the anti-drum bar under the tank. I spotted this had fallen off, but my practised mechanic's eye told me that the bar clearly didn't hold the tank on so had obviously only been put there as a bit of BSA frippery. So I didn't bother to replace it, and smugly congratulated myself on improving the power to weight ratio. A few weeks later I started to occasionally notice a distinct smell of petrol when I braked. The penny finally dropped just after I'd filled the tank and stopped at some lights - huge smell of petrol and a cloud of steam from the front of the bike. Closer examination revealed the steam to be petrol vapour, caused by neat four star cascading from the split across the front of the tank onto the downpipes. Fixing this with Araldite was the first of many maintenance escapades that sort of worked in the short term but were clearly, even without the benefit of hindsight, doomed to failure...

Next problem was the gearbox - the dogs in second gear rounded, so the bike would just jump out of gear. I put this down to my fondness for second - using all the revs available, which meant ignoring the notional 6400 redline (hey - I knew power was good up to 8000 rpm), she'd pull gloriously from around 35 to 70mph, making second my favourite around town gear. I solved the problem by ignoring second for a year, holding first to about 40 or so, then dropping into third. Then, for the latter half of that year, I had dreadful clutch problems - no-matter what I did to adjust it, give it thirty miles and it started slipping, give it another 20 and it started dragging as well. Changing the plates helped a little, but it wasn't until about the fifth time I was sitting on the street looking at the dismantled clutch yet again that I realised the basket had broken. I was wondering once more why the basket didn't actually run on the bearings - there was a bearing plate that the basket just sat on, not actually held or seated by anything, but by now I was used to BSA's sloppy tolerances and dubious designs. Then, as I looked and tried to match the components against the oil stained drawings in my trusty Haynes manual, I realised the basket had broken - the middle of it had fractured all around the bearing housing and what I assumed to be a bearing plate was actually the centre of the basket, edges worn smooth by miles of riding it like that. One basket later and the clutch worked fine.

When the front mudguard brackets fractured I tried the pragmatic approach - remove it. After all, Captain America in Easy Rider didn't need a mudguard, did he? Well, no, but then he also didn't have to drive every day in North Wales. Unusually, once I'd taken the broken mudguard off, it didn't rain for over a week… and then it did.

Driving ten miles in an open face helmet without a front mudguard in the rain is not something I'd recommend. It's not the water that gets you (after all, you get that from rain). No, it's the dirty water.